- What is Contract Manufacturing?

- Advantages of Contract Manufacturing

- The Services of Global Cos

- The Products of Global Cos

- What makes Global Cos stand out from other contract manufacturers

- 3 MORE reasons to do business with Global Cos

What is Contract Manufacturing?

Currently, Contract Manufacturing is considered the easiest way for a brand to manufacture their Private Label products. This is the most popular way for launching a new brand for small and medium sized businesses.

The reason behind that is the intensifying cosmetic market competition. It requires substantial and even not cost-effective investments to start your own cosmetic manufacturing, including purchasing extremely expensive machinery, renting or buying the venue, and employing and training of personnel.

Based on the latest data, global cosmetic market expands by 6,4% annually. According to experts, global cosmetics sales will continue to grow, thanks to the growing population of female consumers aged from 18 to 50, who accounts to 48% of the entire world’s population.

Contract Manufacturing is the shortest, cheapest and the easiest way to place your own unique product on the market.

There are 2 types of Contract Manufacturers:

- the ones who only supply specific types of services

- the ones who offers their clients turn-key solutions for their products

Those who only supply specific types of services

When you source different suppliers in order to produce one product, these things have to be kept in mind:

- One of the suppliers lead time delay can bring the entire supply chain down, when you are developing and producing your product, which will inevitably lead to your product launch delay, and, therefore, potential losses.

- You will have to keep the variety of different and complicated processes under control by yourself, and monitor if each supplier’s obligations are fulfilled.

- When you source separate companies to produce separate parts of one product, spending extra on the transport, logistics etc. is unavoidable.

Contract Manufacturing

Partnering up with an independent Contract Manufacturer, who is able to provide full production cycle services for your product is the most beneficial way to start off. Among the benefits are:

- You only need to provide the basic concept of your new product.

- Your Contract Manufacturing partner will take care of everything: Formula development, Sample production, Packaging design, Preparing necessary documents etc.

- No need to worry about several companies’s obligations and coordinate the lead times.

- The only thing that is required is to confirm the final sample and wait for the finished product delivery!

Undoubtedly, this is the most efficient and profitable way to start a new product (or a product line).

Advantages of Contract Manufacturing

Many companies and entrepreneurs have to face the following obstacles when launching their new cosmetic product:

- Considerable investments have to be made in order to obtain extremely expensive equipment machinery, a production venue, and qualified personnel.

- Complicated bureaucracy associated with the product certification and registration.

- High uncertainty in product launch date.

On the contrast, a full cycle Contract Manufacturing has a lot of advantages.

You can fully concentrate your resources on planning a marketing strategy

After assigning production related responsibilities to your contract manufacturer, you, as the product owner, have significantly more time, which you can dedicate to the marketing strategy planning. This is one of the most evident benefits of Contract Manufacturing.

You can forget about the unexpected expenses and production related risk management

When launching your own cosmetic production, a company has to take care of having appropriate production venues, high quality equipment, qualified personnel, reliable raw material suppliers, a unique and workable product formula, packaging etc.

All of this requires substantial expenses which have to be taken in account when calculating the final product cost. Those risks are minimised when applying for Contact Manufacturing, and if the cost offered by a contract manufacturer is too high, you can just change the manufacturer. In any case, Contract Manufacturing is a much more profitable option than trying to manage the production at your own company’s expense.

With Global Cos, you will receive a full package of production services necessary to obtain a finished and registered product. You will also avoid the expenses of establishing your own production facility. Global Cos’s managers will swiftly process your inquiries, offer a detailed product cost specification, declare the estimated lead time, minimising possible risks and unexpected expenses.

You can launch your product much more promptly

Contract Manufacturing is an option for those wishing to place their product on the market soon. Cosmetic formula development, production and product certification can last a very long time if managed by a cosmetic brand. Sometimes, making a product from scratch lasts months, or even years.

Any cosmetic company is interested in securing their reputation, expanding their portfolio, which depends on mainly how fast the product is launched, and of what quality the product is. By ordering a product at Global Cos, you may receive you market-ready product in a matter of several weeks after the contract is signed.

You are exposed to a much lesser risk

Contract Manufacturing is perfect for projects with high risks of not paying off in the future. When utilising the resources of a contract manufacturer, you minimise the potential expenses that might follow in case of the project not bringing profits.

The Services of Global Cos

Formula development

Global Cos has an extensive range of ready-made formulations for various types of cosmetics products. This company can offer the finished formulas, or, at your request, develop a brand new one, based on your specific requirements.

They use natural ingredients for Cosmetic Manufacturing:

- Plant and herbal extracts

- Natural plant-based oils and essential oils

- Vitamins

- Fruit Acids

- Minerals

Global Cos works only with reliable raw material suppliers, who offers raw materials of the highest quality, always supplied along with the set of all necessary papers. Global Cos stores the materials in quality compliant storage facilities, with all safety, storage and hygienic requirements abided. Thus, they are able to adjust the formulation, by adding one or several new ingredients, even after the production has already started.

Packaging design

Packaging is not only a product container, it can also act as a powerful marketing tool, which may affect your product potential on the market. That is why packaging should get as much attention as the product itself, and should be handled by professionals. Appropriate packaging is primarily important for the consumer, as the thing that makes the first impression. Global Cos are ready to offer the best packaging form and design solution for your product. You will be offered several design options, from which you can chose the one to utilise in the final product. Production is only started after the product packaging design is confirmed by the client.

Product registration and certification

An extensive professional background of Global Cos’s personnel allows them to not only manage typical cases, but, if the client requires, to handle difficult registration procedures and certification. It is also difficult to test the claimed efficiency of the product, but it is necessary. For this, in particular, the help of experienced certification managers at Global Cos will allow you conduct such tests.

A regular cosmetic registration procedure usually includes:

- Formula Development.

- Raw material procurement.

- Sample production and sample testing.

- Technical papers preparation.

- Sample testing results based documentation preparation for further registration.

- Registration process.

- Collecting the state registration certificate.

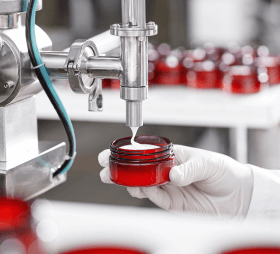

Product Manufacturing

Manufacturing facilities at Global Cos encompass several cosmetic production lines. This allows the company to manufacture several project orders simultaneously and fulfil all obligations successfully. Each production line includes:

- Melters and Greasers. These units of equipment allow to quickly melt solid or frozen ingredients of any kind and maintain them in a molten state at a given temperature.

- Vacuum Homogeniser. Is a machine that allows to produce a nice uniform product texture.

- Homogeniser with cooling function. This machine allows to cool and mix cosmetic products simultaneously.

- Stainless steel blending tanks.

- Boilers and Melters.

- Sterilisation machine to employ various antibacterial techniques.

- Multi-step reverse osmosis water filtering system.

Cosmetic manufacturing process has many important nuances:

- Since the final product has to be able to stay stable at different temperatures, the ingredients have to be carefully picked and balanced together.

- Not a single ingredient can be added to the product without processing (melting, grinding, filtering, cooling and emulsifying etc.).

- Every production process (hydromechanical, mass transfer process, thermal etc.) has to be carefully assigned and monitored for each new product. Even the slightest error at any stage may cause the entire batch to be defected. Thus, the final product will not comply with declared product claims or even with the safety regulations.

Global Cos is a high-capacity production facility, which allows it to simultaneously manufacture:

- Up to 30 000 product units a day;

- Up to 1 000 000 product units a month.

All production lines at Global Cos are automised. The Safety Control is conducted with the help of complex computer technologies. This eliminates errors that can be caused by «human factor», and prevents production errors.

The Products of Global Cos

Global Cos manufactures more than 50 types of cosmetic products from 7 most demanded categories on the market:

- Face and skin care.

- Cosmetic products for children.

- Body care.

- Hair care.

- Oral care.

- Personal hygiene.

- Make-up.

Global Cos will be happy to help their customers to pick the right product category and product form, if they are hesitant in which form to produce their product. Based on the recent industry trends, the most popular product forms for cosmetics are creams and gels.

An increasing market competition and constantly expanding product form range forces manufacturers to turn their immediate attention from solely marketing strategies to product safety and stability requirements, that are becoming consistently more strict with each year. The finished product has to comply with all safety requirements and state regulations. Unfortunately, not all cosmetic contract manufacturing companies tend to follow those safety regulations.

By placing your order at Global Cos you can rest assured that your product will be absolutely safe, stable, complying with all safety regulations, and supplied with the set of all necessary paperwork.

What makes Global Cos stand out from other contract manufacturers?

Full production cycle

Global Cos offers a full production cycle solution for your product: from concept development to finished product. The client only has to tell the managers what kind of cream, scrub, shampoo, gel or any other product, they want to be produced. Shortly after that, product development begins. It consists of several stages:

1. Product requirement specification. Product requirement specification is a list of the customer’s requirements for the product they want to order. It may include technological processes requirements, and production terms. Also the specification has to include the product category, which the client wants for their future product.

2. Formulation Development. After product requirement specification is made, Global Cos specialists will start the unique formulation development based on proven scientific research tests, and using only the most equipped and advanced laboratories.

3. Sample production and testing. As soon as the sample is ready, laboratory tests begin (Global Cos does not do animal testing!). This is compulsory for checking product stability and its safety regulations compliance for further product registration and certification.

4. Packaging. Global Cos also offers product packaging design services. Based on the clients requirements, the designers will offer several packaging design concept options. These concepts can be further adjusted to fully meet the client’s requirements and vision.

5. Contract. After the sample is confirmed, managers will offer the client to initiate contract signing process. The contract will include all production terms and parties’ liabilities.

6. Mass production. After the contract is signed, Global Cos will start mass production immediately. Since Global Cos’s clients include both large and small companies, the Minimum Order Quantity (MOQ) for Contract Manufacturing is 5000 units.

7. Finished product registration and certification. Global Cos prepares a full set of documents required for further product registration and forwards them to state registrations bodies. The client only has to receive the certificates after they’re ready.

Professional Team

Global Cos’s personnel includes numerous outstanding professionals: engineers and chemists, quality controllers, technicians, mechanics etc. Each one of them has a university degree and extensive professional background. They are eager to develop and create a unique product, that will fulfil all your expectations, and comply with all quality and safety requirements.

The technicians will create the product formula and supervise the production technological process.

Upon the client’s wish, the team of designers will create product design concepts, based on the client’s specification and current industry trends. Global Cos cooperates with only reliable suppliers. Before starting business with anyone, Global Cos undertakes a scrutinised audit of every potential supplier. This helps to avoid bad quality packaging.

Chemists will check if the future product formulation can be utilised safely.

Microbiologists will check each product batch at every production stage for microbiological purity: both after preparation of cosmetic product and after packaging.

Not only products get analysed for the presence of microorganisms in general and specific pathogenic microorganisms. Constant microbiological control is carried out for all equipment involved in the production process as well.

Cosmetics produced by Global Cos comply with the requirements of Russian and International standards, and the safety of products is ensured by Technical Regulation of the Customs Union 009/2011.

Engineers will select and set up the machinery that will be used to manufacture the product.

Quality controllers will check the final product against the standards compliance requirements.

Packers will pack and prepare the batch for shipment as soon as possible.